Umshini

-

I-GRG fiberglass iqiniswe uphahla lwe-gypsum

1. Uphahla lwe-Actomatic GRG gypsum lunezinga eliphezulu lokuzenzakalela, ukusebenza kwemishini elula, kudingeka kuphela ukwenza ukuqeqeshwa kokusebenza okufanele

ukusebenza, ukonga abasebenzi, ukunciphisa izindleko zabasebenzi, nokuthuthukisa ukusebenza kahle komsebenzi.

2. Akukho mkhawulo endaweni yokukhiqiza, inqobo nje uma indawo yokukhiqiza iphephile futhi nezinsiza seziphelele

ngamanzi nogesi ukusebenza.

3. Custom processing, kungenziwa egcizelele ngokuvumelana nezidingo zamakhasimende, kudingeka kuphela ukunikeza usayizi we

umkhiqizo.Vumela ikhwalithi yomkhiqizo iqinisekiswe, gwema ukumosha, futhi wenze umphumela wokucubungula umkhiqizo ube ngcono.

4. Ukwakhiwa kwezinto zokukhiqiza kulula futhi ayikho imingcele yesifunda.

-

I-PVC gypsum board production line

Ukukhiqizwa kwebhodi le-gypsum ye-PVC kufaka phakathi umshini webhodi losilingi we-gypsum elaminethiwe, umshini wokusika we-plasterboard, umshini wokupakisha webhodi le-gypsum nokunye.

-

Umshini wokusika onqenqemeni we-Fiberglass Ceiling board

1. Umshini wokusika onqenqemeni lwe-fiberglass usetshenziselwa ukusika imiphetho namakhona ebhodi, bese uwashintsha ngamathuluzi okusika ahlukene.Amaphethelo namakhona ebhodi le-fiberglass angacutshungulwa emaphethelweni ahlukene nasemakhoneni, njenge-tegular edge, ukufihla umkhawulo nokunye.

2. Ububanzi besayizi yebhodi elisebenzayo (590-610mmx590-610mm).

3. Amakhona aqediwe abushelelezi futhi mahle, awekho imiphetho enzima.

4. 99.8% ukunemba.

-

I-high speed dispersion mixer

Isingeniso 1. Uma ushukumisa futhi uhlakazwa, ukumuncwa komoya kuncane kakhulu, futhi imiphumela yokuxuba nokuhlanganisa mihle.Ngokushukumisa isivinini esiphakathi nendawo noma esiphezulu, ukuhlakazeka kungenza into encibilike ngokushesha futhi izinhlayiya zibe zincane.Izinhlayiya ezinhle kakhulu eziqinile zengezwa oketshezini ukwenza izinhlayiya ezimisiwe.Izici zezinhlayiya ezimisiwe ukuthi azikho ngaphansi kwamandla adonsela phansi kanye nemvula.2. Ubuso bezinhlayiya eziqinile bu... -

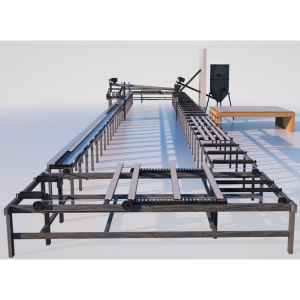

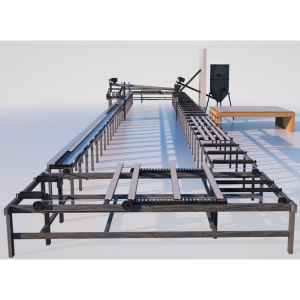

Umshini wokusika we-Fiberglass board ngokunemba

Umshini wokusika ibhodi we-Fiberglass usetshenziswa okwesibili ukusika, wenze umsebenzi wokusika ebhodini osetshenziswe umshini wokusika ongenalutho ngaphambili, ungasikwa ngokosayizi obekiwe.Iphutha lobude nobubanzi bepuleti elisikiwe lingaphakathi kwebanga elingu-+-0.1mm.

-

Umshini wokupenda we-Fiberglass mat

1. I-Fiberglass mat yokudweba umshini ingasetshenziselwa ukufafaza ingilazi ye-fiber mat surface.Imibala ehlukene ye-glass fibre mat ingafuthwa ngokwezidingo.

2. Ukufafaza okuzenzakalelayo kanye nokujika okuzenzakalelayo kuyo yonke inqubo.

3. Ngomugqa wokumisa, ukomisa okuzenzakalelayo ngemva kokufafaza.Izinzuzo: izinga eliphezulu lokuzenzekelayo, ukusebenza kwemishini elula, inqobo nje uma ukuqeqeshwa okulula kokusebenza kungase kube emsebenzini, kusindisa abasebenzi, ukunciphisa izindleko zabasebenzi, ukuthuthukisa ukusebenza kahle komsebenzi. -

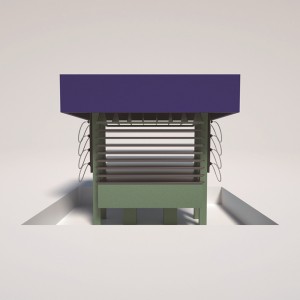

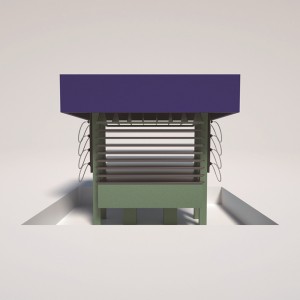

Umshini wokucindezela oshisayo we-Fiberglass Ceiling board

1. Umshini wokucindezela oshisayo we-Fiberglass usetshenziswa umshini wokucindezela ophezulu kanye nezinga lokushisa eliphezulu ukuze ukhiphe ukotini we-glass fiber ube yi-substrate yobukhulu obuhlukahlukene kanye nokuminyana ngokwesidingo.

2. Futhi ungasebenzisa ukuma okuhlukile kwesikhunta ukuze ucindezele ngokuqondile ukuma kwegagasi nokunye.

3. Ingakwazi ukulawula isikhathi nezinga lokushisa, izinga eliphezulu lokuzenzakalela.

-

Fiberglass mat sticking machine

Umshini wokunamathisela we-Fiberglass mat osetshenziswa kakhulukazi Ukufafaza ingcina phezu komhlaba ngokuzenzakalelayo nangokulinganayo endaweni yebhodi yokubeka i-laminating.

-

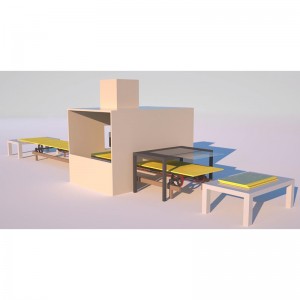

Umshini wokukhiqiza i-Gypsum cornice

Ukugeleza kwenqubo

Ukuhlanza isikhunta okuzenzakalelayo—isikhunta esizenzakalelayo—i-automatic feeding grouting—vibration—automatic threading—automatic hanging net—mold forming—molding—automatic return, futhi abantu abangu-7 kuphela abangahlangabezana nezidingo zokukhiqiza.

-

Umshini wokusika i-Fiberglass mat

1.Le Fiberglass mat cutting maaching esetshenziselwa ukusika i-fiberglass mat.

I-2.Speed singasethwa ngokukhululeka.

3.Usayizi wokusika ungalungiswa ngokuya ngesidingo.